ABOUT US

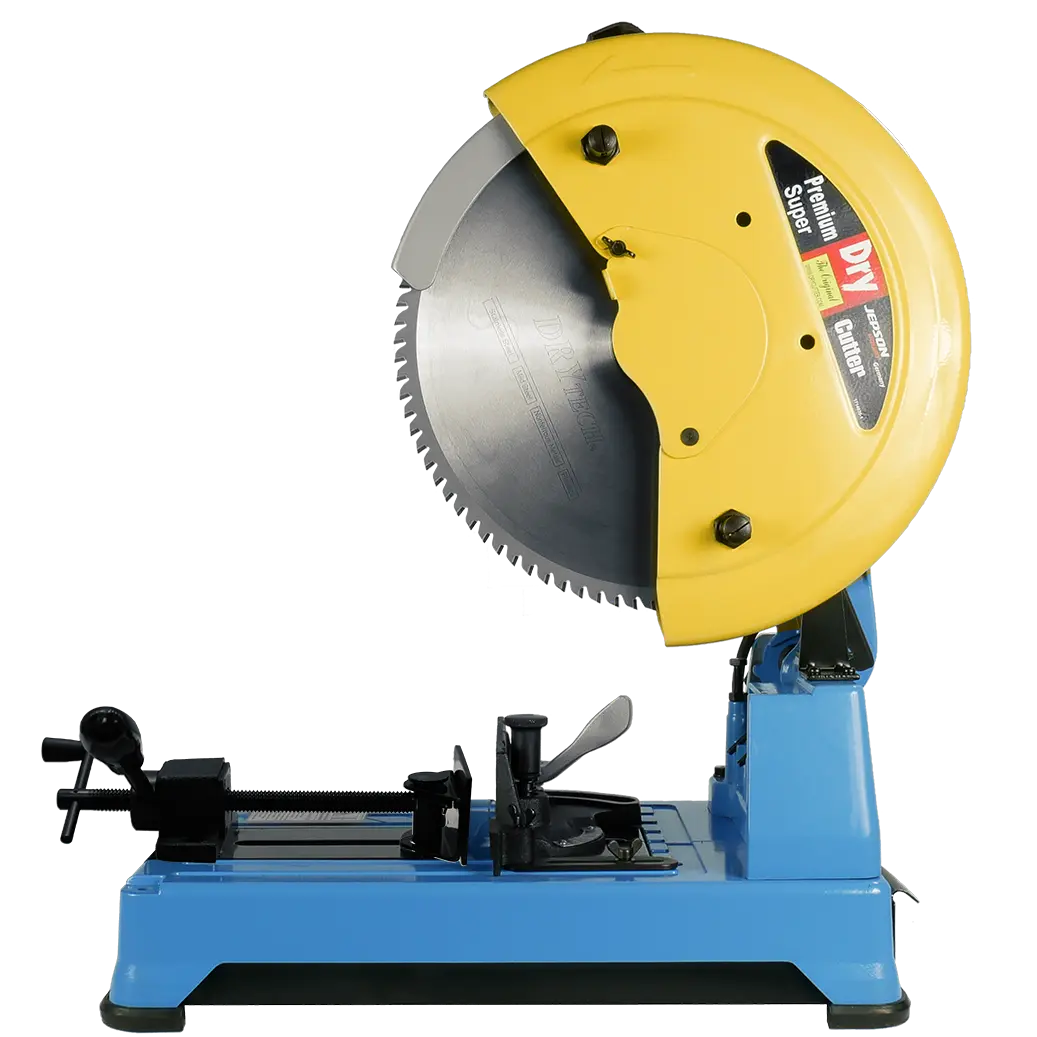

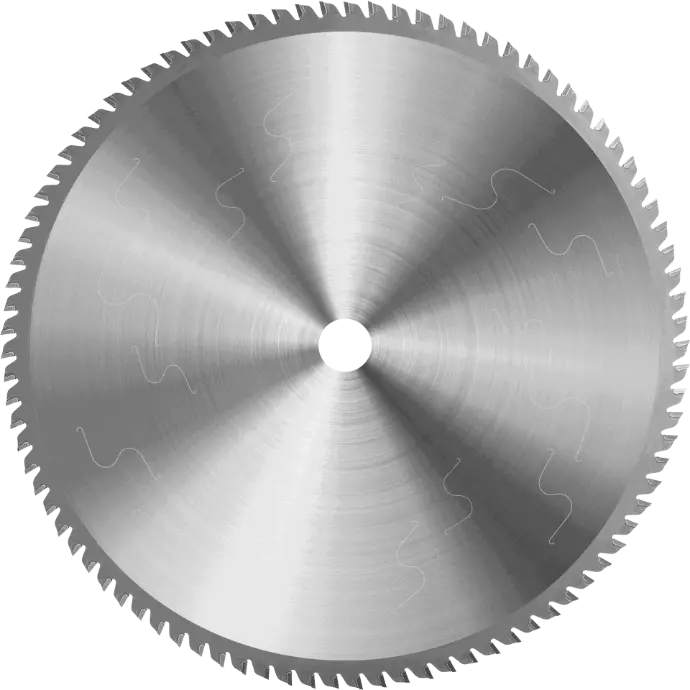

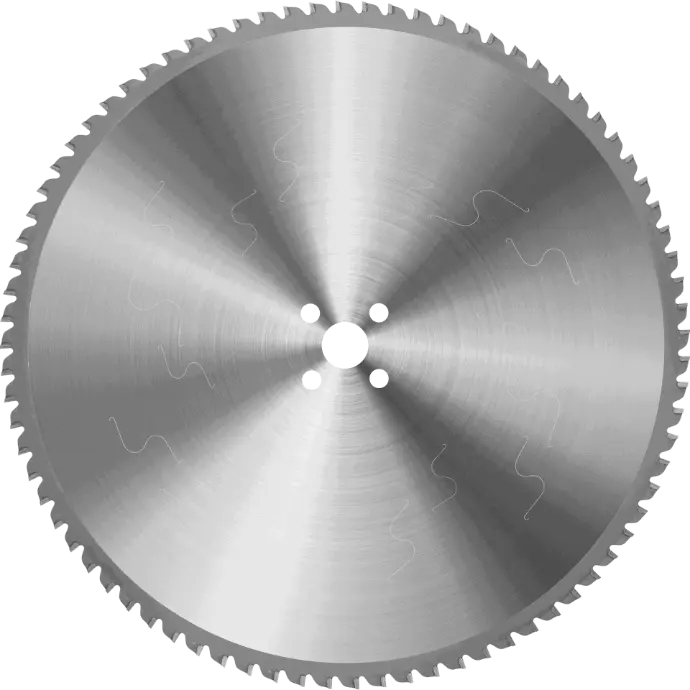

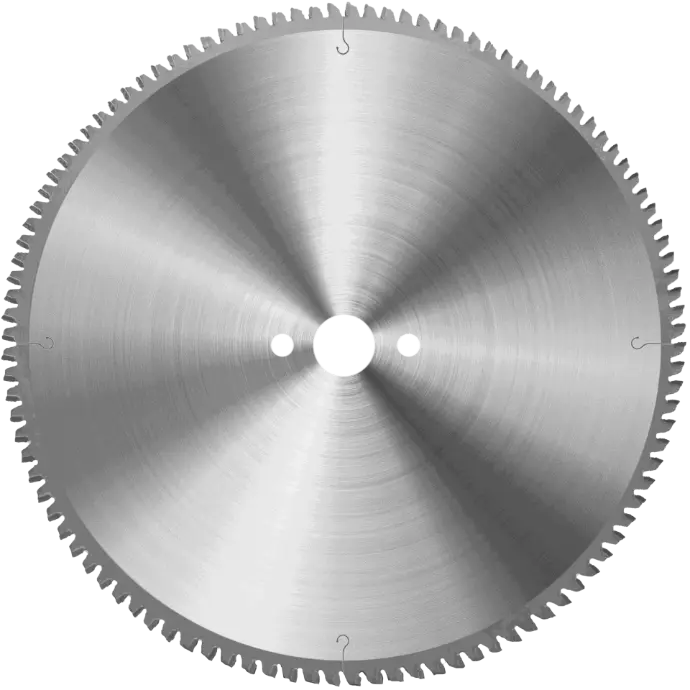

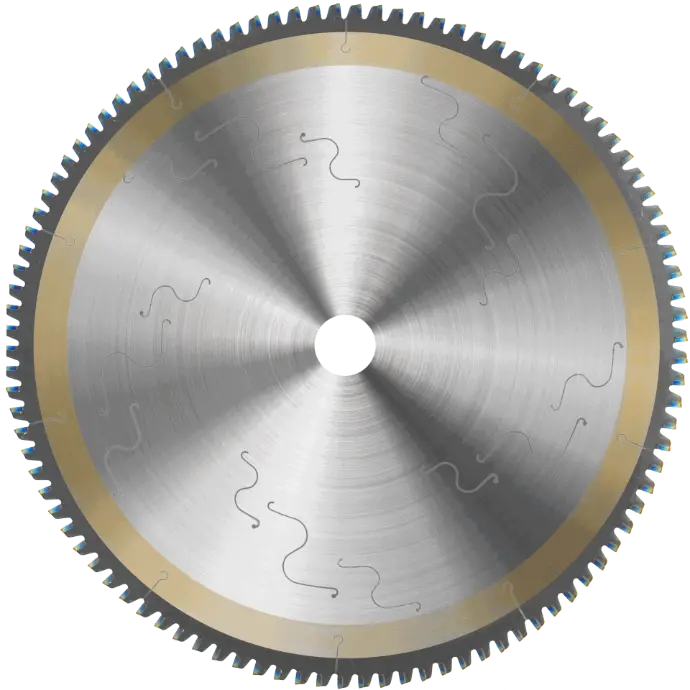

since 1984 this is the guiding principle of Jepson Power - the inventor of dry cutter technology - in the ongoing development of innovative and high-quality machines and saw blades for processing metals and composites. With our technology, the sawing process runs quickly, almost without burrs, without cooling and with a long service life. Thanks to many years of experience, competent product consultants and a Research & Development department, Jepson Power is able to quickly offer innovative and tailor-made solutions such as specially coated saw blades for sawing various types of stainless steel. "

Both our machines and our team impress with the highest performance and resilience.

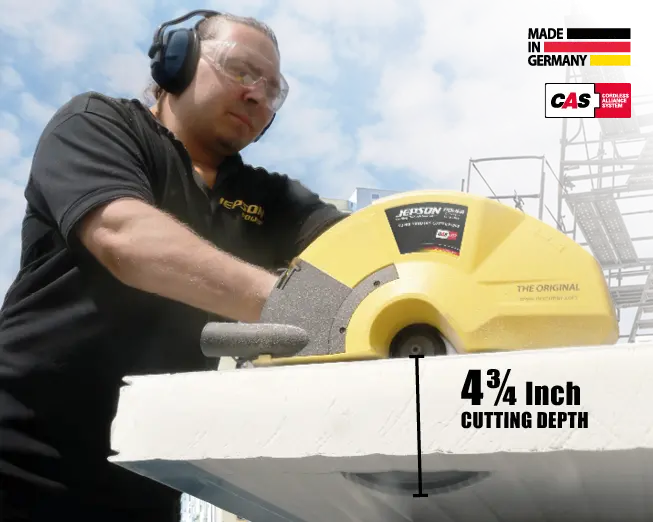

We are constantly on the move, because the next generations of our Dry Cutter machines with their unique saw blades are already being developed and tested in our German production facility in Eschweiler. Our daily incentive: faster sawing, better service life and larger cutting areas!

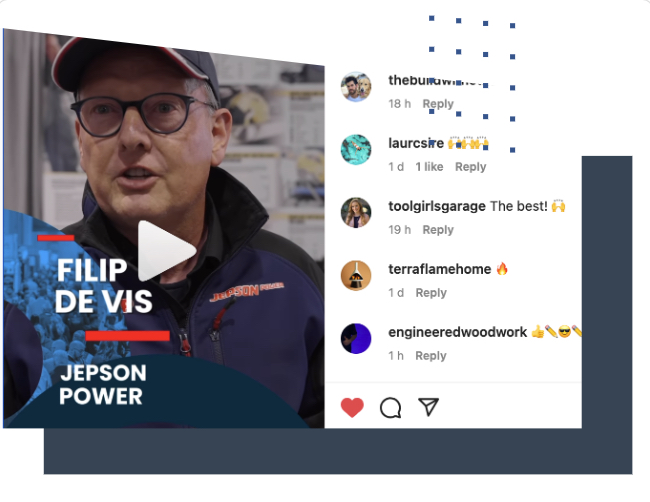

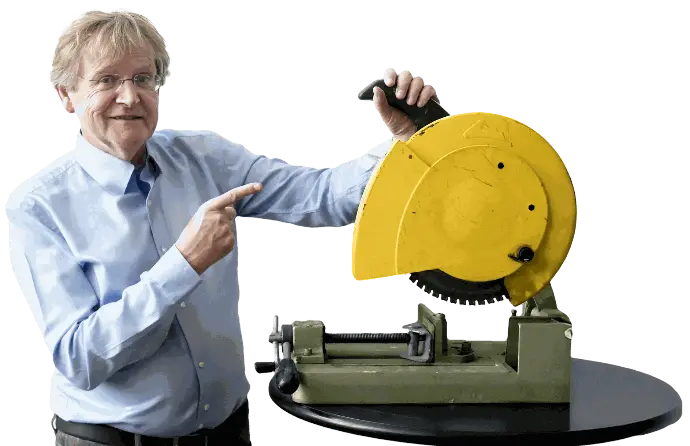

We got the saw on Monday, just like you said. I got it setup and made a few test cuts. It did a beautiful job. I look forward to using the saw for the rest of my career. It should outlast me.

Best dry cut saw i ever used!!!

I've been doing fabrication work of some sort or another, for 25+ years and this saw blows anything I have ever used out of the water! Finishing work after the cut is now optional...because you don't have to do any...incredible!!!!!

Awesome Selection of well made, well thought out saws for Industry and excellent customer service.

Best 2 grand I have ever spent.

The pile of parts with the 35° cuts would have taken most of a full day to accomplish took 2.5 hours.

!

!